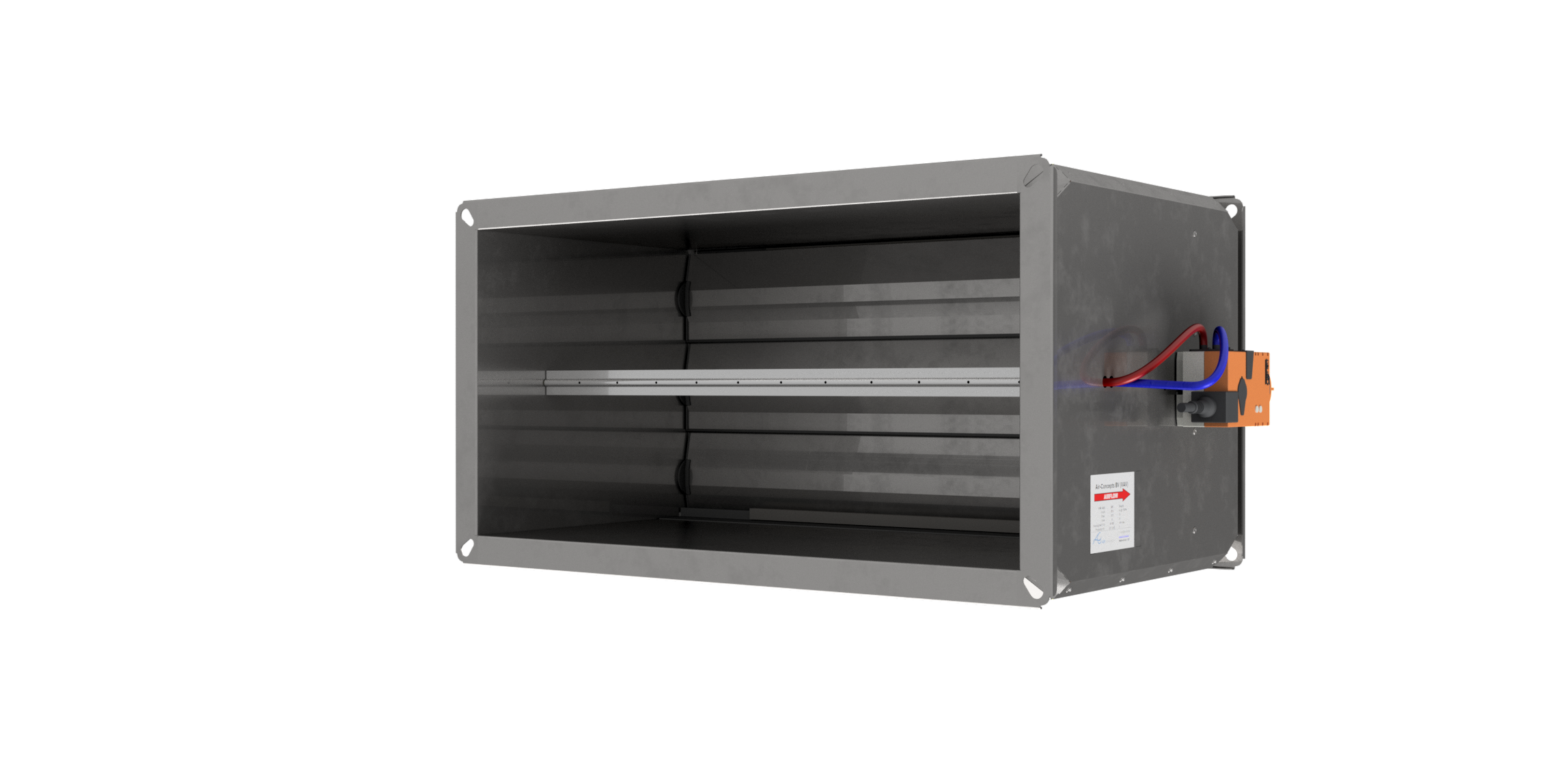

APPLICATION

A variable-air-volume (VAV) system is an air conditioning system designed to control the air distribution in a building based on the demand of the occupants. In a VAV system, the air supply to different zones in a building is controlled by means of adjustable dampers (VAV units) in the air supply ducts. The VAV system can also be used to control the air quality in the building and can be integrated with the building management system (BMS), giving the occupant control over the system settings.

FEATURES AND BENEFITS

- The measuring cross, FloXact™, is very accurate due to the robotized production method. It has a maximum deviation of 2% at 3xD straight flow.

- The FloXact™ has a linear gain factor of up to 2.5x, and measures according to the Log-Tchebycheff method.

- Due to the special profile shape of the FloXact™ it can control from 0.7m/s inlet velocity and has a very wide control range.

- Housing: Magnelis steel (S235+ZM310). This is steel with a modern surface treatment. It has a very high corrosion resistance, is less harmful to the environment and has a beautiful appearance (comparable to anodized aluminum).

- Airtight class C according to EN-1751

- Standard size 200×100……..1200X1200

- Damper blade standard version: profiled Magnelis steel blades, 100 mm. Air tightness class 1 according to EN-1751.

- Damper blade airtight design: Extruded aluminium blades 100 mm. Air tightness class 1 according to EN-1751

- Bearings and gears:Nylon maintenance-free

- Operating temperature +5 °C to 50 °C

- Storage temperature -5 °C to 70 °C